Sales and operations planning, often abbreviated to S&OP, is the cross-functional process of assessing customer buying habits to ensure a company is able to meet the forecasted production, distribution, and purchasing demands required of it.

S&OP is typically conducted by executive-level management professionals on a monthly basis and allows them to better align their plans with company-wide objectives.

One of the most common organizational issues is misalignment between sales and operations teams. Fortunately, this problem is easily fixed via sales and operations planning that is profit-centered and focused on building relationships between company departments.

What Is Sales And Operations Planning?

Sales and operations planning is the process of managing a business’s key components, such as sales, finance, and the supply chain. Small companies with only a few business processes may not need robust sales and operation planning, but as businesses grow, leadership should implement S&OP, in order to:

- Gauge whether staffing levels are adequate

- Define short- and long-term goals

- Evaluate whether sales territories are performing as expected

- Determine whether to allocate budget for new priorities

- Improve resource planning

The sales and operations planning process relies heavily on data and the ability to analyze it in different ways. S&OP software makes it easy for managers to find data and set up reports that help them evaluate key business functions and employee performance.

Methods Of Sales And Operations Planning

Sales and operations planning is crucial to the financial well-being of most companies. As such, it’s important to have all stakeholders present for S&OP process meetings, including sales reps, production, human resources, engineering, marketing, new product development (NPD), inventory/backlog, strategic initiatives, and financial teams.

The sales and operations planning process can be handled in one of two ways, depending on the unique situation your organization finds itself in:

Top-Down Planning: This approach to sales and operations planning focuses on a single sales prediction, upon which management professionals base their strategy and allocate their resources as needed.

Bottom-Up Planning: This approach to S&OP is often used in situations where manufacturing timetables are inconsistent. Rather than basing plans on a specific sales forecast, a strategy is built from the bottom up by assessing what’s needed to produce specific products and/or services within a reasonable timeframe.

Whichever approach your company decides to take, ensure the representatives present for each department have the authority to make on-the-spot decisions. If they don’t, your S&OP process flow will quickly grow stagnant and unproductive.

7 Benefits of Sales and Operations Planning

Now that we know what is sales and operations planning, we can discuss why it’s advantageous. Here are seven benefits to the S&OP process:

1. Eliminate Departmental Silos

The real value of S&OP lies in the collaboration opportunities it creates. By eliminating departmental silos, every facet of a company is able to align using common data points, which often leads to increased accuracy, better efficiency, and lower costs.

Organizational collaboration is a hot-button topic in 2023. But unless every department is aligned via a single S&OP process, it’s nearly impossible to achieve.

2. Improved Inventory Management

Inventory management can make or break a business. If your team doesn’t produce enough products, customers will grow impatient and angry as they wait for their orders and your brand’s reputation will suffer. But producing too many products is equally hazardous. A warehouse full of unsold goods can quickly lead to cash flow issues.

Because an S&OP plan analyzes consumer buying habits, as well as a company’s ability to meet potential demand, inventory management greatly improves.

3. Increased Throughput

Throughput, if you’re not familiar with the term, is defined as “the rate of production or the rate at which something is processed.”

Solid sales and operations planning will allow your company to create more products in less time because the processes for doing so will be more efficient and the necessary amount of resources will always be allocated to the right tasks.

Additionally, this increase in productivity will lead to financial savings. After all, the less time your team spends creating products, the less costly said products will be to produce.

4. Higher Product Quality

Fortunately, increasing throughput does not impact product quality. In fact, a sales operations plan should actually lead to better products than your company was able to previously produce.

Why? It all has to do with efficiency. An efficient process will naturally minimize mistakes, thus allowing your organization to quickly pump out higher quality goods. Furthermore, better products lead to business savings. Every flawed product your company produces must be remade, resulting in wasted materials and/or employee resources.

5. Reduced Lead Times

We touched on it briefly, but it bears repeating: sales and operations planning will shorten lead times, thus improving customer satisfaction in the process.

We live in a microwave society. When your customers order a product, they want it now, not later. By improving inventory accuracy and making sure your organization always has the proper amount of products in stock, your customer will receive their orders in a timely fashion.

Fair or not, Amazon set the bar with its two-day (sometimes even quicker!) shipping policy. S&OP will ensure your company is able to reduce lead times and come closer to meeting customer expectations in this regard.

6. Better Customer Service

Exceptional customer service is a staple of successful business. By producing better products and delivering them to customers in a timely manner, you’ll be able to elevate your brand in the eyes of its target market.

Happy customers are generally life-long buyers. Since it costs five times less to keep a customer than it does to generate a new one, it’s important to ensure customer satisfaction. Additionally, happy customers have the potential to become brand advocates, which can turn into a valuable marketing channel for businesses.

Both customer retention and advocacy are more easily achieved when an effective sales and operations planning process is in place.

7. Higher Profitability

Higher profitability is a result of the six other sales and operations planning benefits we just discussed. If your company is able to eliminate organizational silos, predict inventory requirements more accurately, boost throughput and product quality, and better serve its customers, higher profitability is almost inevitable.

Greater efficiency is always beneficial to businesses. S&OP allows companies to intelligently streamline operations in order to boost profit numbers.

Challenges of Sales And Operations Planning

Implementing S&OP does come with some challenges. The primary challenge is getting buy-in from leadership — the manager who sees a need for S&OP may need to convince financial decision-makers that the benefits of S&OP outweigh any expenses.

Depending on the size of a business, several people may need to be involved in the development and implementation of S&OP. To avoid the challenges of miscommunication and a prolonged implementation, it’s helpful for one person to spearhead the S&OP initiative, set agenda for discussions, and define a timeline for launching any new processes.

Common Steps in the S&OP Process

The S&OP process can be broken down into six essential steps: data gathering and forecasting, demand planning, production planning, pre-SOP meeting, executive S&OP meeting, and the S&OP strategy implementation.

Let’s take a look at each of these steps in greater detail:

1. Data Gathering: The sales and operations planning process consists of a series of meetings, the first of which is designed to gather data in order to accurately forecast the future. During this meeting, information from previous sales and industry trends are assessed and future predictions are made.

2. Demand Planning: This step requires collaboration between multiple departments to complete properly. Executives from sales, operations, marketing, etc. come together to adjust inventory levels, marketing and sales strategies, and customer service policies to match the data gathered in the previous step.

3. Production Planning: Next, company leadership analyzes their company’s supply chain in regards to capacity. They’ll decide if the current set up — manpower, machinery, suppliers, etc. — are adequate for their forecasted needs. A supply plan is then crafted on the decision they reach.

4. Pre-SOP Meeting: This stage of the S&OP process requires leadership personnel from multiple departments to meet, collaborate, and evaluate the financial ramifications of the forecasted demand and supply plans.

6. Exec S&OP Meeting: Next, leaders from finance, sales, operations, marketing, and other relevant departments meet once again to discuss all data previously gathered and develop a viable sales operation plan to implement.

7. Finalize and Implement S&OP: Finally, once the S&OP plan is finalized and approved, it’s implemented and monitored for effectiveness.

By conducting each of the meetings above, you’ll be able to implement a winning sales and operations plan for your organization.

Key S&OP Metrics

Sales and operations planning isn’t a one time event. Your S&OP plan must be monitored and evaluated on a regular basis, as we mentioned. To do so, pay attention to the following metrics:

Demand Forecast Accuracy: Did you accurately forecast demand, or were your projections off? Continually assess how on-target your forecasts are.

Inventory Turnover: Related to demand forecast accuracy, how quickly are you turning over inventory? As quickly as you thought you would?

On-Time Delivery: It’s important to analyze your supply chain and ensure your team is delivering products on time. If not, you likely have a supply chain issue that needs fixing.

Order Accuracy: Similarly, it would also behoove you to monitor your S&OP plan for order accuracy. Speed is great, but not if you’re quickly producing subpar work.

Total Sales: Moving on to financial S&OP metrics, total sales numbers will help key you in to how healthy your organization is in the monetary department.

Gross Margin: Hopefully, your total sales meet your projected targets. Equally as important, ensure your gross margin is hitting company projections too.

Working Capital Projections: Does your company have as much working capital in the bank as your team forecasted? If not, it’s time to evaluate why and adjust projections.

There are plenty of other key S&OP metrics you could measure as well. But the seven listed above are important and will get your evaluation efforts started off on the right foot.

Tips for Improving Your S&OP Process

At this point, your sales and operations planning process should be in place. Congratulations! But your work is far from over.

To ensure the S&OP plan is as effective as it possibly can be, keep these sales and operations planning best practices in mind:

1. S&OP Should Start at the Top

Your sales and operations planning efforts will only be successful if company leaders buy-in and lead the charge. Without executives, the process will get bogged down as lower-level employees continually seek approvals.

Plus, upper management sets the tone and mentality for the entire company. When every day team members see their bosses making a point to prioritize the S&OP process, they’ll naturally learn to prioritize it too.

2. Clearly Define the End Goal

What is your organization trying to achieve by implementing a sales and operations planning process? Inventory optimization? Reduced supply chain costs? Maybe you want to improve demand forecasting accuracy.

Whatever your objective, make sure it’s clear to all at the beginning of your S&OP process flow. That way everyone involved knows what they’re aiming for and can collaborate cross-functionally to achieve it.

3. Know Your Sales Numbers

It’s common knowledge that sales are hard to forecast. There are just too many variables to effectively predict the number of sales a company will make within a given time frame. But that doesn’t mean you shouldn’t even try.

By studying your sales numbers from months and years past, you can work out future sales projections with reasonable accuracy.

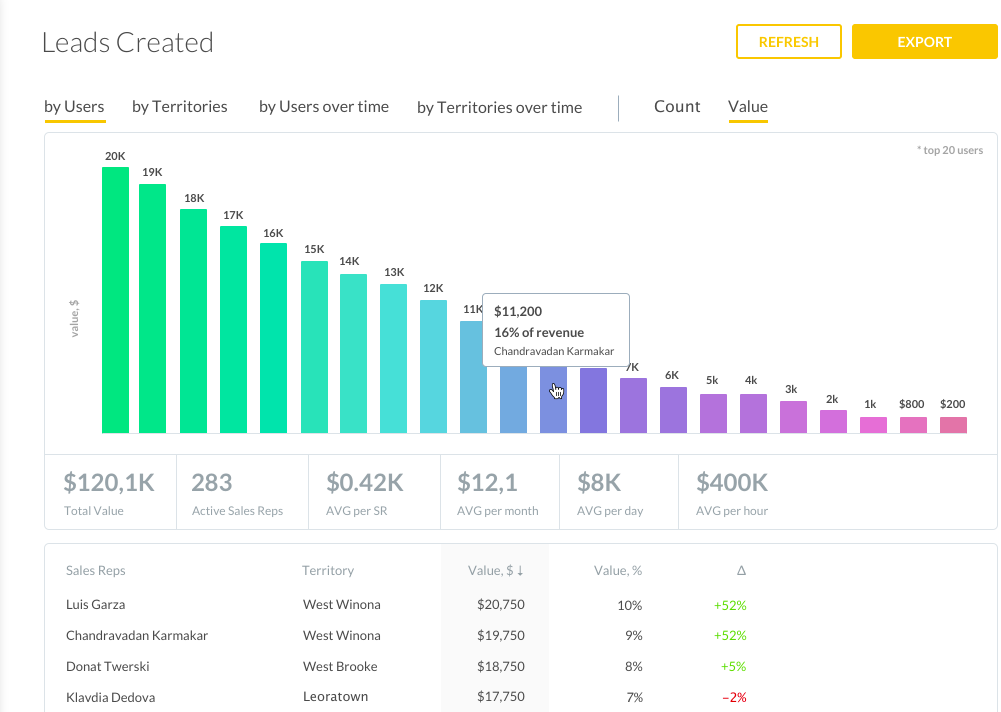

Image: SPOTIO Executive Insights report.

This information can then be used during the sales and operations planning process to better predict supply and demand needs.

A tool like SPOTIO will give you accurate, real-time information regarding your team’s sales numbers, which can be used to improve your forecasting efforts.

4. Plan for the Unknown

Nothing in life—or business— is guaranteed. As such, it’s vital that you plan for the unknown. Have contingency strategies for multiple scenarios. If you lose your biggest client, how will your company pivot? If you land a new mega-account, how can you meet the new demand?

You can’t plan for everything, nor should you try. But having a few backup strategies in place is just smart business and should become a part of your sales and operations plan.

5. Understand the Impact of Supply and Demand Changes

If you don’t understand how supply and demand changes will affect your organization, you’ll likely run into problems—problems that could easily be avoided with a deeper understanding of the chain and time spent modeling different scenarios.

For example, were you to land a new account and increase production to meet heightened demand over the next six weeks, modeling will be able to tell you what kind of short-term financial setbacks you’re likely to incur, as well as long-term benefits. Management can then use this information to make more informed decisions.

Do your company a favor and study your supply chain by modeling different scenarios and understanding how certain changes affect your company as a whole.

S&OP Software

The good news is, there are great S&OP software solutions to help you implement and monitor everything we’ve covered in this article. Here are a few top options:

SAP Integrated Business Planning

SAP Integrated Business Planning is a popular solution for S&OP purposes. The tool features scenario planning and simulations, social collaboration, and powerful predictive analytics. When combined together, these capabilities ensure organizations are able to plan their resources effectively and monitor their results with ease.

SAP Integrated Business Planning is available for purchase as a monthly subscription, though pricing details are not listed on its website. Contact a SAP representative for more information.

Infor Sales and Operations Planning

Infor Sales and Operations Planning is another great tool for S&OP purposes. Like its competitor, SAP, the Infor solution allows users to easily monitor sales and operations.

A few specific features include the ability to synchronize supply and demand imbalances, evaluate “what if?” scenarios to master the connected value chain, and visualize data to quickly compare to multiple statistical forecast models. Infor also comes with 24/7 elite support.

Pricing information is not available on the Infor website. Contact the team for cost details.

SPOTIO Field Sales Engagement Platform

Lastly, we have SPOTIO, wish is not a traditional S&OP software. But it does have valuable tools, which companies can use to better manage outside sales reps, plan sales strategies, forecast future results, and measure sales team success. This is important information to have when sales and operations planning.

From lead generation solutions to appointment setting options to CRM integrations, SPOTIO is packed with the features you need to both sell and make solid business decisions. Request a free demo today and see the software in action for yourself.

The Value of S&OP

Business leaders may recognize the value of sales and operations planning, yet not know how to implement it. With the right software — like SPOTIO — companies can begin the S&OP process immediately, focusing on essential business functions, then expanding S&OP to other areas over time.

SPOTIO gives you the real-time data you need to make better business decisions, improve your forecasting, and troubleshoot underperforming territories. It also helps sales reps work more efficiently, eliminating the need for tedious administrative tasks.

Let SPOTIO help you with your S&OP.